Timber Sheds vs. Rolled Steel and Beyond: The Durability Debate

When it comes to sheds, longevity and durability are key considerations for homeowners and businesses alike.

In New Zealand, Timber sheds, particularly those built from treated pine, are renowned for their long lifespan, often outlasting their rolled steel counterparts.

Let’s dive deeper into why timber sheds are such a durable option and how they compare to rolled steel sheds, and then take a look at other materials like LVL and MSS beams.

Why Timber Sheds Last Longer

Timber sheds are well-known for their impressive longevity, with many lasting between 50 to 75 years — or even longer! This durability is due pine which is treated under high pressure to ensure the chemicals deeply penetrate the wood. This treatment protects the timber from decay and ensures the shed remains structurally sound for decades, even in harsh weather conditions.

As a result, timber sheds typically come with a remarkable 50-year building consent, which is the longest available. This extended consent period speaks volumes about the shed’s quality and how councils trust these structures to remain in top condition for decades.

When you compare this to the warranties on other materials, the 50-year building consent is impressive!

Rolled Steel Sheds: A Shorter Lifespan

In contrast, rolled steel sheds are usually made from 1.2mm to 3mm thick steel that’s pressed into shape. These sheds rely on their shape for strength, not the thickness of the steel itself. As a result, rolled steel sheds typically last only 15 to 30 years, depending on environmental factors like weather. Most rolled steel sheds come with a 25-year building consent, which reflects their shorter expected lifespan compared to timber sheds. The reliance on shape for strength means that steel sheds can be more susceptible to damage. A small knock or dent in the steel can compromise the structure’s strength, leading to expensive repairs or even the need for replacement. This is a major drawback compared to timber sheds, which are less prone to such damage.

Salt Spray and New Zealand Conditions

One important factor to consider in New Zealand is the impact of salt spray, which affects nearly every location in the country because of our long coastline. Salt spray accelerates corrosion, making rolled steel sheds more vulnerable to rust and structural damage over time, particularly along the coast.

Timber sheds, on the other hand, use timber that’s been specifically designed to withstand salt exposure, giving timber-framed sheds an edge when it comes lasting on the coast.

Cost-Effectiveness and Construction Time

When it comes to price and construction time, timber-framed sheds generally have the upper hand too.

They’re are often cheaper to build, and also have more straightforward foundation requirements. Steel sheds require a structural floor with an engineer’s sign-off, as they rely on the slab for strength. In many cases timber sheds are simply concreted into the ground with basic ground cover, making them an attractive option for anyone looking to save time and money.

Long-Term Value

Choosing between timber and rolled steel sheds depends on the long-term value of the shed. If you’re building a shed on a property you plan to sell in the next few years, rolled steel might be a more cost-effective choice. However, if you’re in it for the long haul, with a lifespan that’s at least twice as long as rolled steel sheds, timber sheds offer a better return on investment and a lower cost of ownership over time.

Exploring Other Materials: LVL and MSS Beams

At SHEDS4U, we generally use timber poles and framing to ensure maximum strength and durability.

However, when larger clearspan sheds (over 7 meters wide) are needed, we also offer LVL beams (Laminated Veneer Lumber) and MSS beams as alternatives to steel rafters. Here’s how they compare:

LVL Beams:

- Lightweight: Easier to handle and install, reducing labour and machinery costs.

- Cost-Effective: Generally cheaper in material and installation costs.

- Sustainable: Made from renewable wood with a lower carbon footprint.

- Better Insulation: Wood naturally provides better thermal performance.

- Non-Corrosive: Less prone to rust compared to steel.

- Strong Load Capacity: Suitable for residential or low-load structures.

MSS Beams:

- Strength-to-Weight Ratio: High strength with less weight, making them easier to handle and install.

- Cost-Effective: Use less material while maintaining load capacity.

- Faster Installation: Easier to install than heavier steel beams.

- Higher Load-Bearing Capacity: Can support more weight than LVL beams at a lower weight.

Heavy Hot-Dipped Galvanized Rafters:

- Durability: Excellent corrosion resistance, ideal for harsh environments.

- Longer Lifespan: The galvanized coating extends the rafter’s life.

- Higher Load Capacity: Can support heavier loads than LVL or MSS.

- Strength: Maintains structural integrity in extreme conditions.

So, what does that all mean?

When all is said and done, a Timber pole shed is hard to beat for long-term value, especially those made from pressure-treated pine as all our sheds are. They offer a 50 to 75-year lifespan, cost less to build, and require fewer structural requirements. Rolled steel sheds may seem a quicker, cheaper option in the short term, but they cannot match timber sheds for longevity and value.

As mentioned above timber sheds are more resistant to salt spray and New Zealand’s coastal conditions, making them a better choice for our unique environment.

At SHEDS4U, we’re proud to provide timber pole sheds that offer exceptional durability, value, and long-term performance. Whether you’re after a simple shed or a large clearspan structure, we have the materials and expertise to meet your needs.

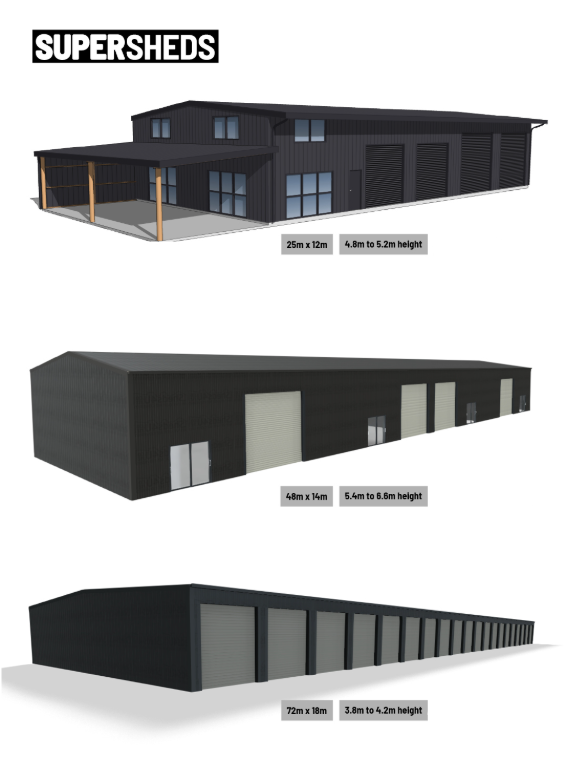

Get in touch today, and check out our really big industrial buildings!